PREMIUM line Software

Measuring made easy.

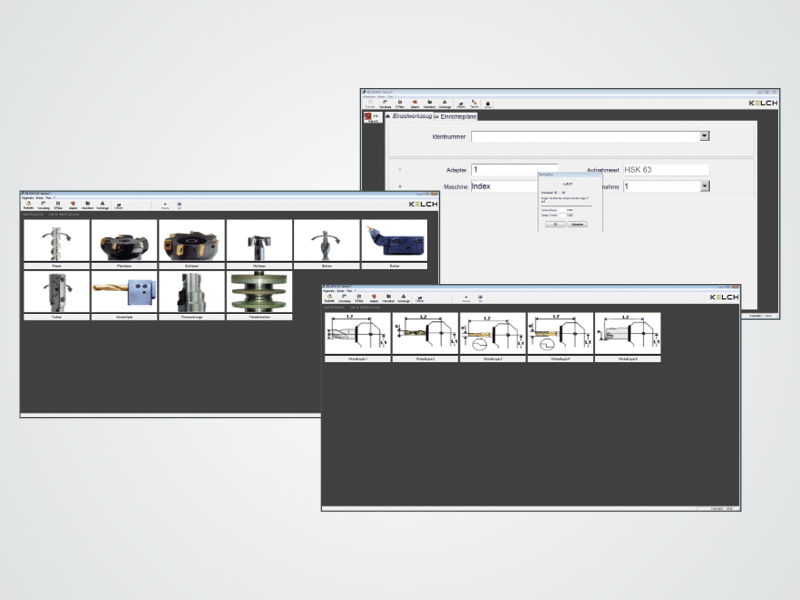

Measuring simply could not be easier with this software – and no special knowledge is needed. The clearly arranged user interface enables users to immediately navigate around the system using familiar forward/backward movements. A simple clear homepage is the direct entry to each measuring task. Other input screens, such as Picture Start, guide users step by step to the correct measuring result and also to the automatic measuring program. Adapters, machines, original tool forms, tooling plans and measuring processes are saved in the integrated database. The standard configuration includes bidirectional data communication (DNC) via a network card or serial interfaces in the KELCH data standard.

Measuring made easy.

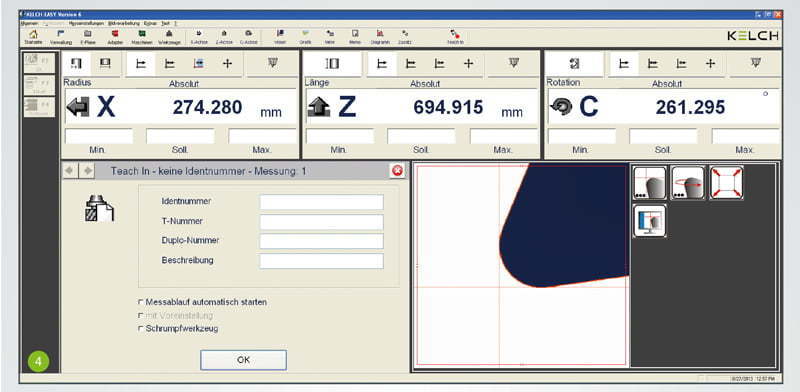

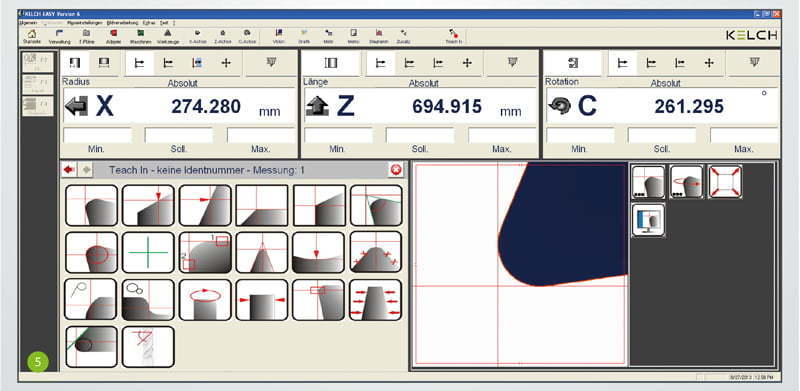

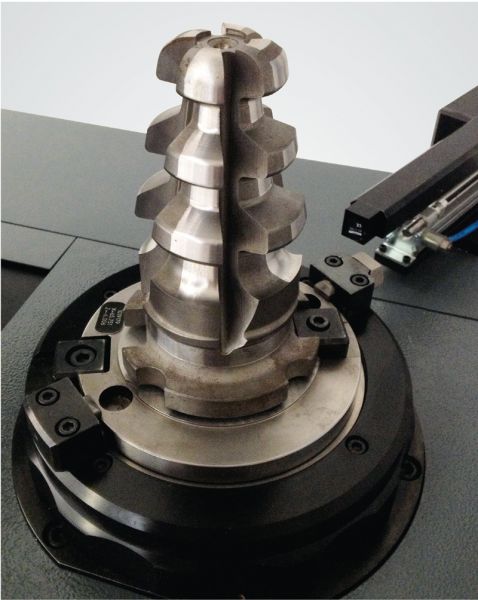

Complex tools can be measured fully automatically for the first time with the Teach-in software option. Fully automatic measurement guarantees precise measuring results and enables tool presetters to be operated regardless of the operator's knowledge and expertise. All measuring steps are retained and can be saved as a complete measuring program with the tool. EASY leads each user securely through the program with Picture Start using concise, easily understandable input dialogs. Practical pictures and graphics help with navigation and orientation.

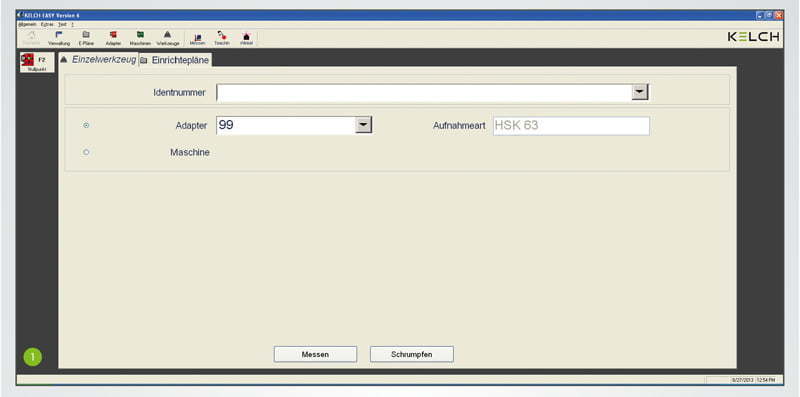

Step 1: Input the measurement of individual tools or entire tooling sheets on the homepage. Then select the appropriate adapter on the tool presetter. If one of the tools entered has already been saved, the system calls it up by its identification number and immediately begins the measuring process.

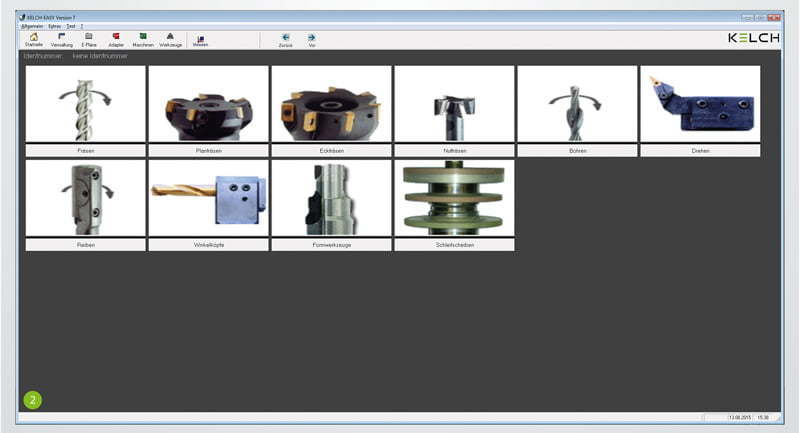

Step 2 Select a tool using Picture Start. The selected tool then performs the measurement. Picture Start is KELCH's own in-house developed selection menu. Define the tool group you require using the different graphics. Simply click on the right graphic depending on the tool type and cutting geometry.

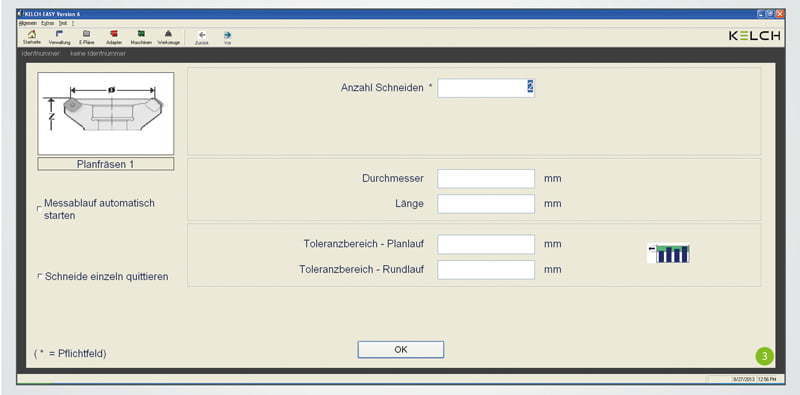

Step 3: Use ParaDirect (PaD) for inputting data. This is a concise, easy-to-understand input dialog into which you enter the target dimensions and tolerances. Simply complete the mandatory fields for the measuring process. The corresponding measuring process begins when you have confirmed by pressing Enter. The data is entered from the PaD and the required measurement results are instantly available. Any actions required are clearly visible on the monitor.

It couldn't be EASIER.

The new user interface for the tool presetter's software delivers the most precise measuring results and is easy to use and understand. The familiar Home-Forward-Back navigation is similar to the method used in most browsers. meaning that you can return to the starting point by pressing just a single button. EASY software also comes with online Help, which is also easy to understand and structured in a similar

way to Windows.

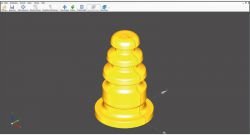

A fully functional 3D model in three steps

The 3D wizard lets you create a 3D model of the entire tool in a few steps, allowing you to use it for collision observation. The EASY software records a point scan of a rotationally symmetrical tool with a contour scan, generates a 2D model, which can still be processed to close the contour gaps, and then extrapolates it into a 3D model. Issuing the file in .igs, .stp and .stl format enables the model to be used by the majority of simulation tools.

The intelligent solution.

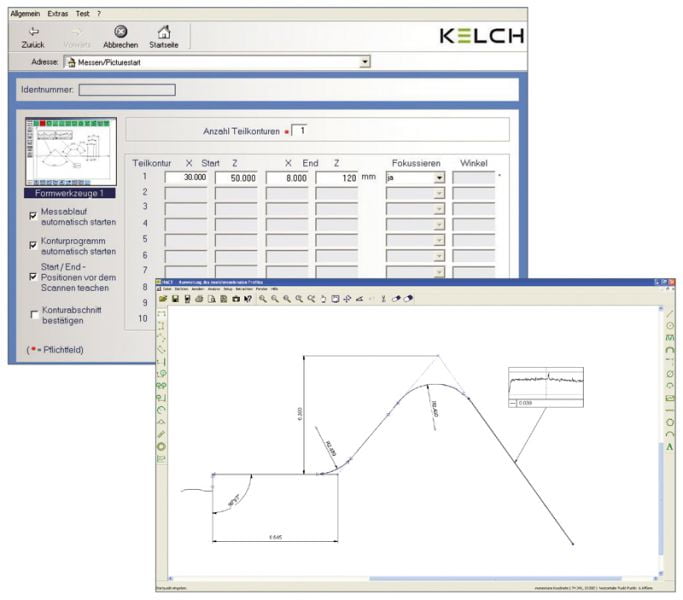

KELCH Contour Software is ideal for automatically checking tool contours for straight or spiral grooved forming tools. After defining the start and end points, the contour is scanned in one or more partial contours. The recorded point coordinates are interpreted in an analysis programme and converted into a polygon. All geometrical elements can be extracted and dimensioned from the calculated, graphically displayed contour and also compared with the target contour. The geometrical comparison can be undertaken using specific data, such as target radius, angle or distance, or deviating from a predetermined optimum contour which is imported in DXF format, for example. Irregularities in individual elements can be displayed particularly clearly. The measurements determined and learnt in this way are saved as a reference file and are then available for the next measurement. The complete process therefore runs automatically from scanning to logging.

The Contour Software package offers the following:

Technology

- Simple contour comparison using DXF files

- Measurement of any geometry elements through to the quality of surface and shape

- Straight and circular shapes can be formed from segments

- Extensive analysis is also possible via auxiliary elements

- Measurement of straight-grooved or

spiral-toothed forming tools - Contour scanning with 3-axis CNC equipment

- Synchronised switching

- Intuitive graphical interface

- Measurement of any distances, angles and radii

- Comparison with the target contour

- Tolerance observations

- Clear logging

Everything at a glance!

KELCH measuring software ensures that you can always save tool-based data and transmit it to the right place. It does not matter whether the data comes from machine controls, tool management programs, CAD/CAM systems or other manufacturing systems. Now you always have the same consistent data throughout the entire system –missing data is now a thing of the past. This also prevents simple errors, as can be caused by transposed digits, thereby improving process reliability and also efficiency within your company.

Regardless of whether you opt to use CoVis, or EASY,

KELCH helps you to conveniently transmit tool-based data by

data transfer to the right place.