Why KELCH?

In the design and development of setting devices, one important point always plays a central role.

always plays the central role: the use of the optimum material.

Two components already specify the requirement for this - the guide rails and the spindle. Both the guide rails and the spindle are made of hardened steel. Soft metals cannot be used for this purpose. The use of other materials for the base body, the turret and connecting parts leads to a mix of materials that must be avoided at all costs.

In many companies, the setting devices are not located in an air-conditioned room,

therefore temperature differences of 10°C are quite common (summer: approx. 17°C in the morning

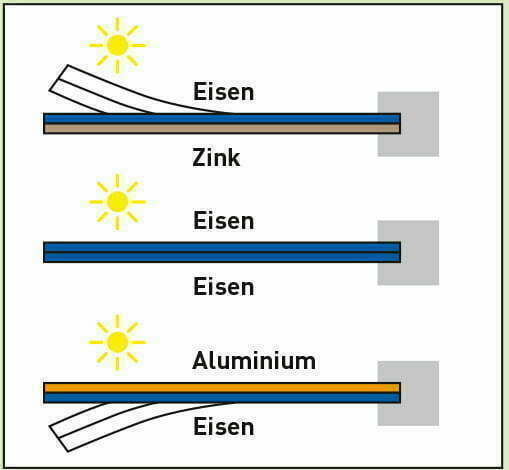

- approx. 27°C in the afternoon). This means that a 600 mm long object made of aluminum expands by 0.140 mm when the temperature increases by 10°C. If steel and aluminum are now combined (guide rails and spindle on aluminum base body), this creates a bimetallic effect and warps the entire geometry. In a comparison of materials, granite has the lowest coefficient of expansion and looks best at first glance, but if you consider the bimetallic effect, granite is also not ideally suited. The most suitable materials are therefore those with similar

to the same coefficient of linear expansion.

KELCH has therefore always relied on gray or nodular cast iron in order to achieve the optimum material mix. The mineral casting used in the new KENOVA set line V9 and V9-S series of instruments is also specially matched in its mixture to the required material properties.

As a result, our setting devices guarantee reliable geometric alignment with a reliable zero point that does not "wander" with fluctuating temperatures.

If unsuitable materials are used, this zero point displacement must be

must be constantly compensated by system calibration.

In order to offer you a reliable long-lasting product, we do not save on

on the material and use only the highest quality materials.

This table clearly illustrates the differences in the material and the corresponding behavior with temperature fluctuations.

| length- elongation- coeeficient X x 10-6 | Linear expansion (object length = 600 mm) Δ T = 1K | Linear expansion (object length = 600 mm) Δ T = 10K | |

|---|---|---|---|

| Aluminium | ∼ 23 | ∼ 600,014 | ∼ 600,140 |

| Granit | ∼ 3 | ∼ 600,004 | ∼ 600,020 |

| Grey/spheroidal cast iron* | ∼ 12 | ∼ 600,007 | ∼ 600,070 |

| Mineral casting* | ∼ 12 | ∼ 600,007 | ∼ 600,070 |

| Steel* | ∼ 12 | ∼ 600,007 | ∼ 600,070 |

Representation of the linear expansion of different materials

at a temperature expansion of 1 or 10 Kelvin.

* used at KELCH

Darstellung des Bimetall-Effektes bei Temperaturschwankung