Safecontrol 4.0

2. August 2023

KELCH introduces KENOVA set line V244

6. May 2024

Safecontrol 4.0

2. August 2023

KELCH introduces KENOVA set line V244

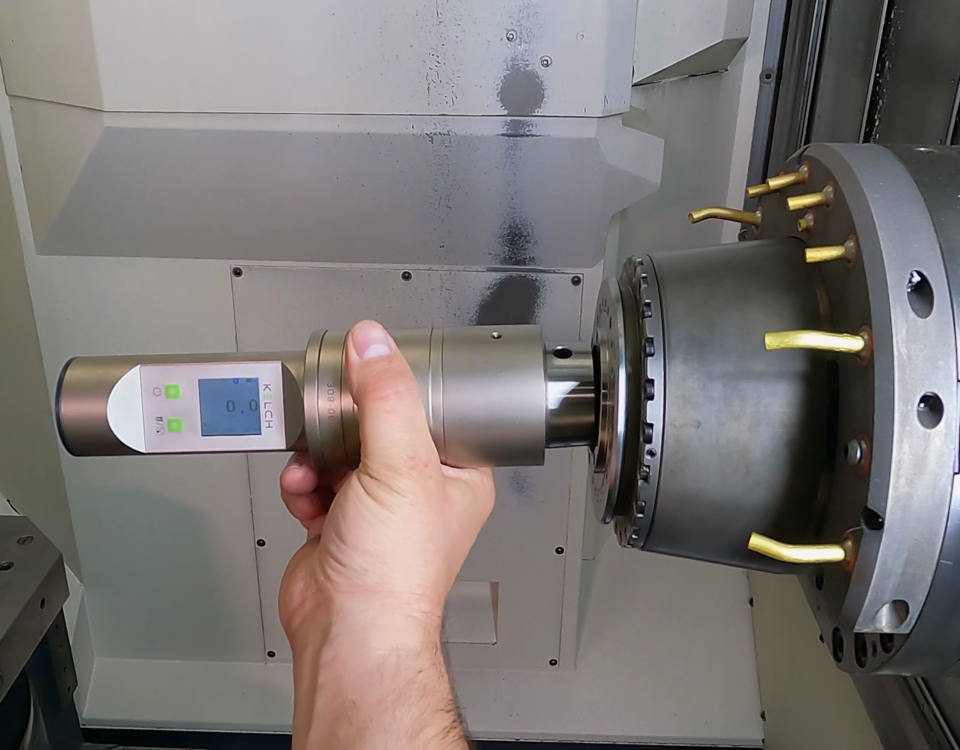

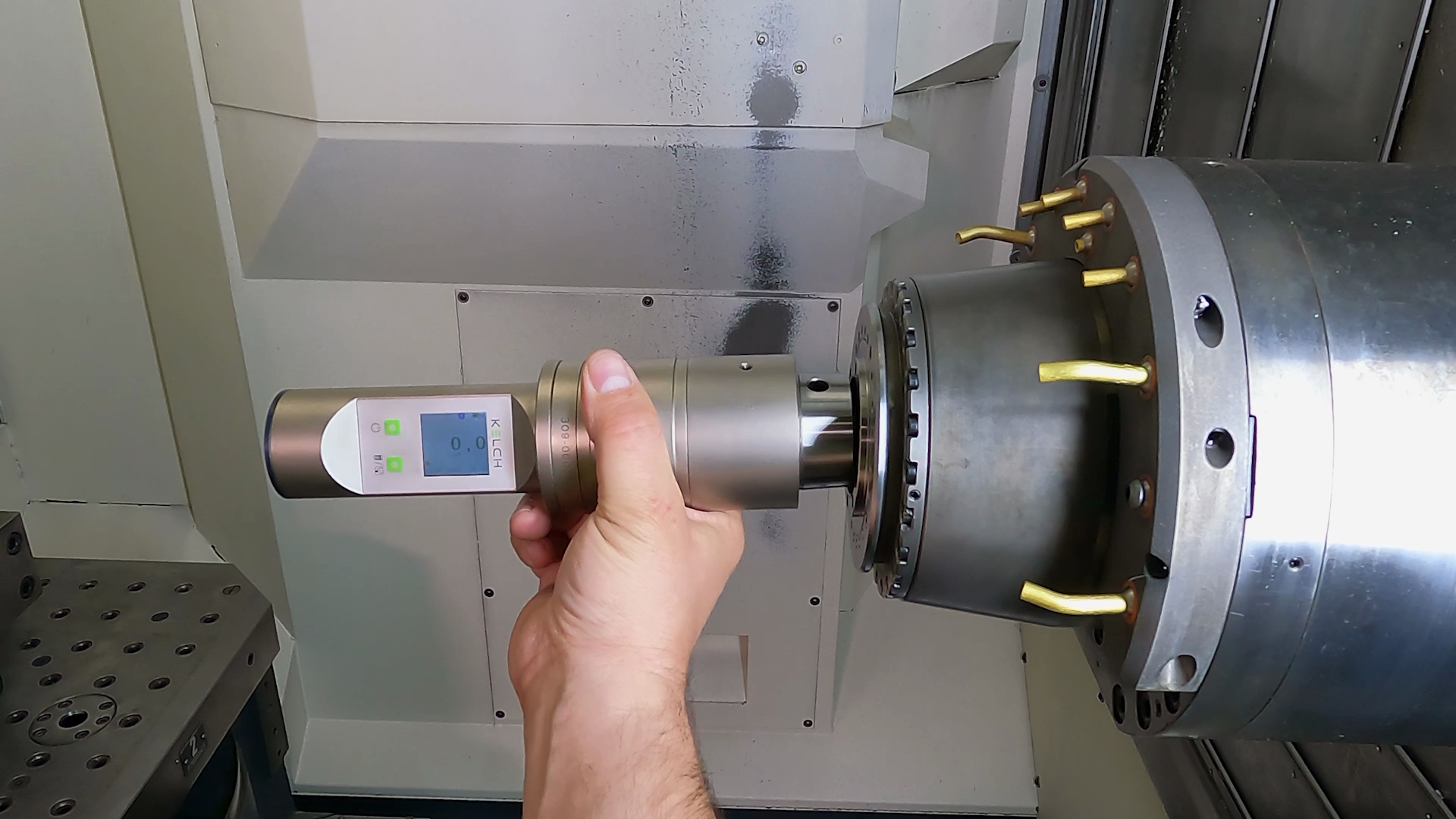

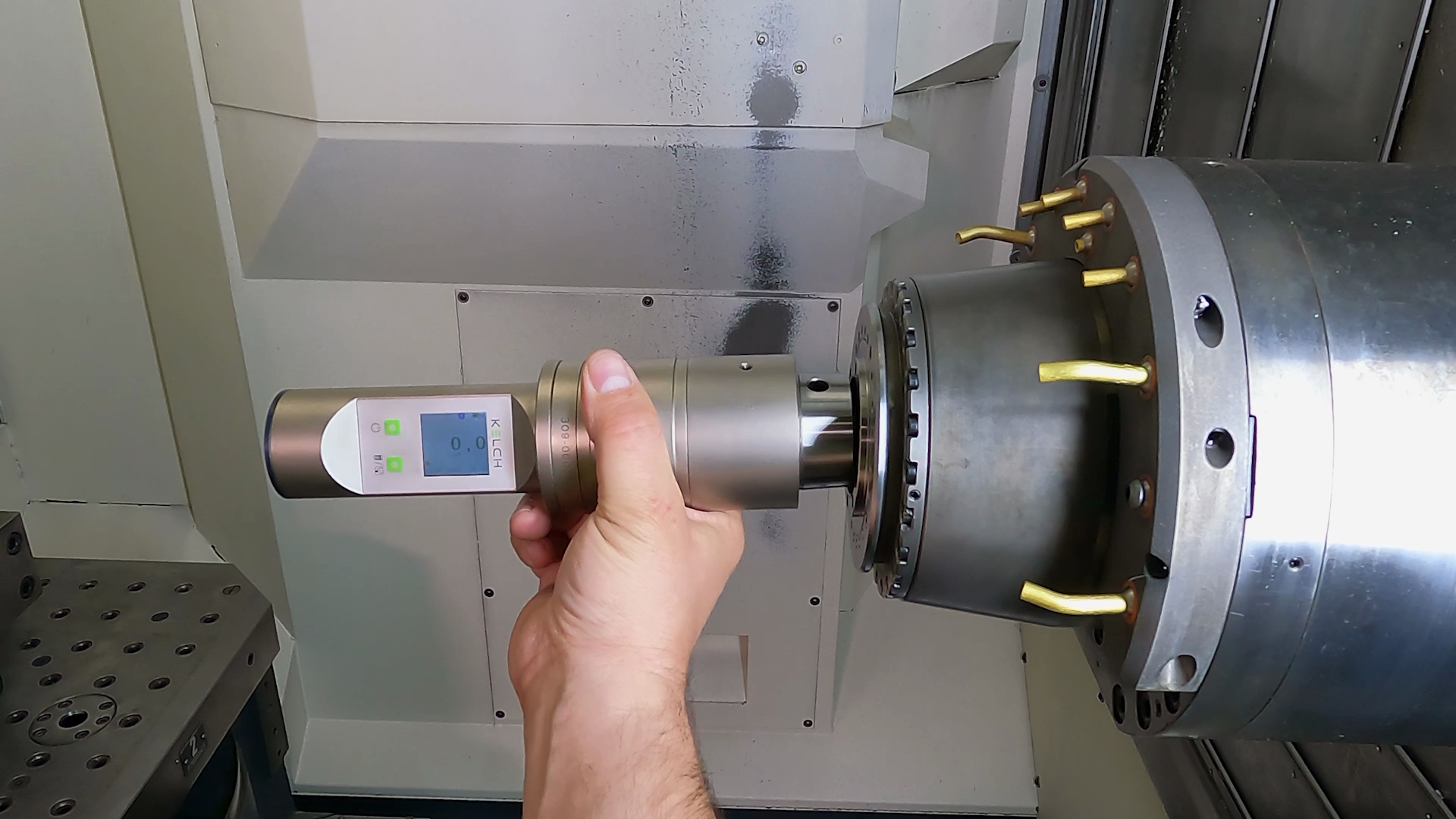

6. May 2024Weinstadt, 06.05.2024 – Clean tool holder cones ensure precision at the interface, thus ensuring quality and process reliability in manufacturing. For professional cleaning of tool holders, KELCH is soon launching RoWi III. The new generation of the modular cleaning device features ergonomic design and useful additional features. The device effectively cleans heavily soiled or resinous tool holders and is available either as a custom installation in CNC machines or as a flexibly deployable tabletop device.

RoWi III features a new, ergonomic design and is significantly lighter than its predecessors. The cleaning unit offers an innovative clamping principle for DIN and MAS BT steep taper cones. Additionally, for the first time, internal cleaning of the HSK cone and thus cleaning of the clamping slope are possible. A timer ensures effective application without unnecessary waiting times. Cleaning attachments are available for all common cone sizes in HSK, PSC, and SK. RoWi III consists of a drive unit with an alternating current motor for approximately 65 revolutions per minute and various cleaning attachments, each with three brushes for different cone sizes. Only grinding brushes are used for cleaning, as they reliably remove contamination without causing mechanical abrasion.

High exchange precision – less scrap Before use in the machine tool, cleaning the tool holder cones ensures high exchange precision. At the same time, precision at the interface preserves the concentricity of the tool system, resulting in less scrap. After use, RoWi III can remove chips and emulsions from the tool holders. Once a cone is inserted, the machine automatically cleans for one minute, allowing the operator to prepare for the next step. Apart from emptying the dirt particles or replacing the brushes, RoWi III is maintenance-free and resistant to rust and cutting fluids.

Modular design The interchangeable cleaning attachments for RoWi III are available for HSK cones in sizes 32 to 100, for PSC cones in sizes 40 to 100, and for SK cones in sizes 30 to 50. Upon request, additional sizes are also available. A cost-saving advantage for businesses arises from the modular design: They can selectively choose the required attachments in addition to the drive unit, so that costs only arise for the actual need. If the operational requirement changes or new holder cones are added, the system can be expanded with the appropriate attachments.

Machine-specific design RoWi III is available either as a flexibly deployable tabletop system or as a custom installation in CNC machines. The flexible tabletop system can be placed at any location with a 220 V socket. The form-fitting integrated handles support safe lifting of the device during transport. Alternatively, RoWi III is also available for direct use in the machine tool. There, the machine can automatically clean the cone before and after use, ensuring flawless results for the next application as well. For a machine-specific design and installation in the desired machine, machine manufacturers can directly contact KELCH’s experienced teams.

Downloads:

Press Release – RoWi III – New Modular taper cleaner.pdf