24.08.2017 / KENOVA set line V9xx-S – Press release

24. August 2017

17.04.2018 / Safecontrol 4.0 – Press release

17. April 2018

24.08.2017 / KENOVA set line V9xx-S – Press release

24. August 2017

17.04.2018 / Safecontrol 4.0 – Press release

17. April 2018EMO 2017: KELCH launches Safecontrol III

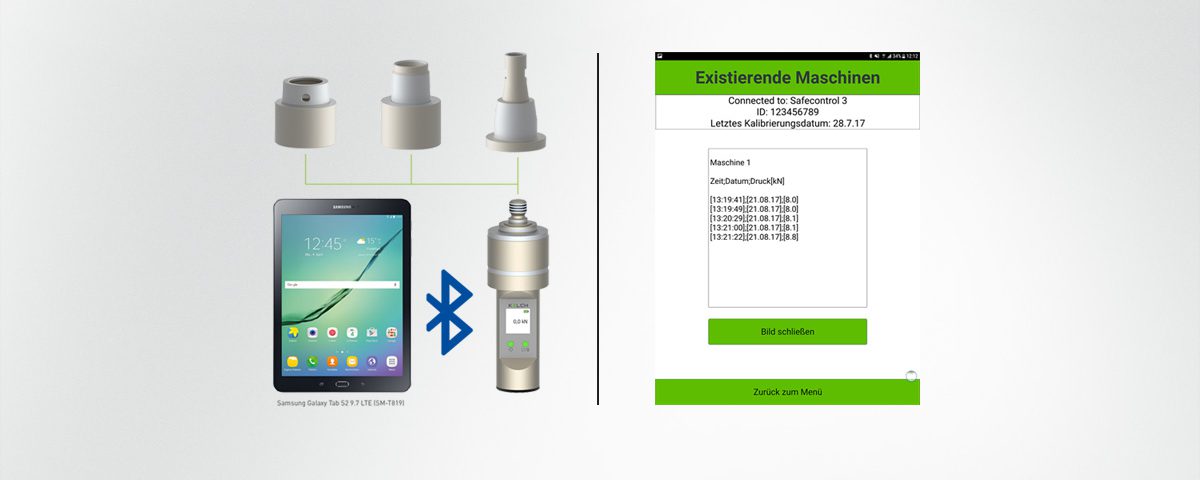

System fully revised, expandable with a tablet solution

EMO Hanover from 18-23 September 2017: Hall 4, Stand C26

Weinstadt, 25.08.2017. Kelch GmbH, which specialises in peripherals and services for manufacturers and users of machine tools for cutting processes, will be showcasing the Safecontrol III system at this year’s EMO in Hanover. The system was developed to measure the pull force of the machine spindle. This is not just an enhancement to the well-known Safecontrol II, but rather a fully revised system with numerous additional benefits.

Saving and evaluating measured values

Safecontrol III spans the measuring range from 2 to 100 KN, meaning that only one base unit is needed for the majority of measuring tasks, a major benefit compared with competitors’ products. The user-friendly design of the unit makes it simple to operate: it simply requires two buttons to switch on the unit, zero it and either save or delete the measured value after measurement. The digital display is used to present the measured values, with an integral position orientation automatically rotating the display so that the operator always has the measured value ergonomically in view. The system consists of a base handle with an interface to all common machine spindles, such as SK/BT 30 to SK/BT 60, HSK 32 to HSK 160 or PSC 32 to PSC 100. The spindle pull force is evaluated in the base unit. All tapered versions can be unscrewed and replaced in seconds. Users can conveniently read the measured values on the display of the base unit. As Safecontrol III stores up to 1000 measured values, hand-written notes are now a thing of the past. Users can now quickly and simply perform the necessary series of measurements. The memory can subsequently be read directly on the PC, thereby ensuring that there is 100% traceable checking of all spindle pull forces for each machine. The saved data can then be statistically evaluated. The Kelch Safecontrol III is available from the end of the year.

“Ready for Industry 4.0”

A unique feature of Safecontrol III is the addition of a tablet solution, with software which communicates wirelessly with the force sensing bar. The principle: The spindles to be measured are identified using a QR code. The system then measures the pull force and assigns the measured value immediately to the right machine spindle in the database. This innovation means that incorrect mapping of results is now a thing of the past. Kelch developers have also adhered to the “Ready for Industry 4.0” mantra and integrated further test functions. The machine spindles are thus fully automatically included in proprietary statistics, ensuring that any trends indicating when spindle pull force is declining are promptly identified. With Safecontrol III, factories can also help to prevent machine damage and consequential costs.

Kelch GmbH, based in Weinstadt near Stuttgart, offers peripherals and services for manufacturers and users of machine tools for cutting processes. With over 100 employees, the company generates annual revenue of approx. €13 million. As a fully owned subsidiary of Harbin Measuring & Cutting Tool Group Co., Ltd. (HMCT), Harbin/China, Kelch is part of the China General Technology (Group) Holding Co., Ltd. (Genertec), Beijing. Genertec is represented in 100 countries worldwide, with 45,000 employees in 51 companies. Kelch GmbH acts as the technology centre for the international business group in Europe. KELCH develops, manufactures and markets tool holders, cleaning devices, shrinking devices, presetters as well as measuring machines and also offers tool management services.

More information at https://www.kelch.de.

Downloads:

KELCH_Safecontrol_III_25082017_EN

Image1_web

Image1_print

Image2_web

Image2_ print

Image3_web

Image3_print