05.02.2016 / kOne Premium

5. February 2016

10.03.2016 / Safecontrol – Press release

10. March 2016

05.02.2016 / kOne Premium

5. February 2016

10.03.2016 / Safecontrol – Press release

10. March 2016High precision ensures optimum quality

Fast, clear and highly precise workpiece measuring

(30th Control – International Trade Fair for Quality Assurance, Stuttgart 26 – 29 April 2016, Hall 1, Stand number 1128)

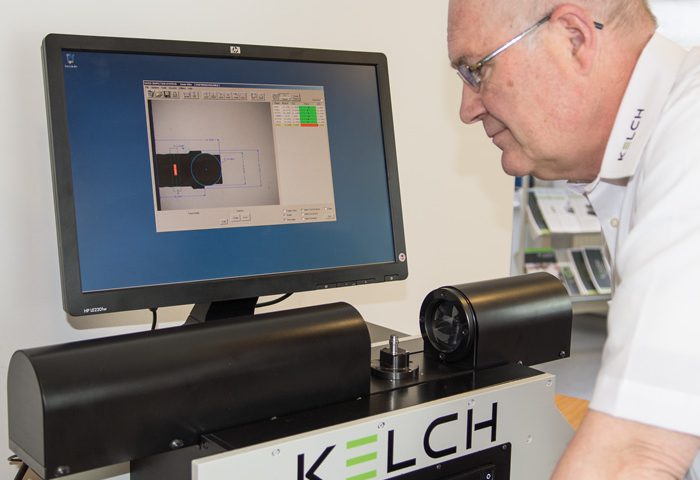

Weinstadt, 09/02/2016. Kelch GmbH offers three workpiece measuring devices in the “KENOVA measure line” range. Rotationally symmetric workpieces from machine tools are measured with speed, clarity and high precision. The special telecentric lens plays an important role for the measurement while the simple design and the intuitive operation are very user friendly.

The devices automatically measure workpiece characteristics such as length, diameter, radius, angle, concentricity, taper and run-out. On threads, criteria such as core diameter, outer diameter and flank diameter are determined with precision and repeatable to a maximum of three micrometers deviation. This applies to the pitch of metric and non-metric threads and even to custom threads. It is also possible to optically measure non-rotationally symmetrical workpieces using the classic transmitted light process. Beforehand, the precision-ground workpiece support has to be replaced with a workpiece holder made of glass. At the core of the device is the optical unit with a telecentric lens and a high resolution camera.

Technical process, integrated software and quality assurance

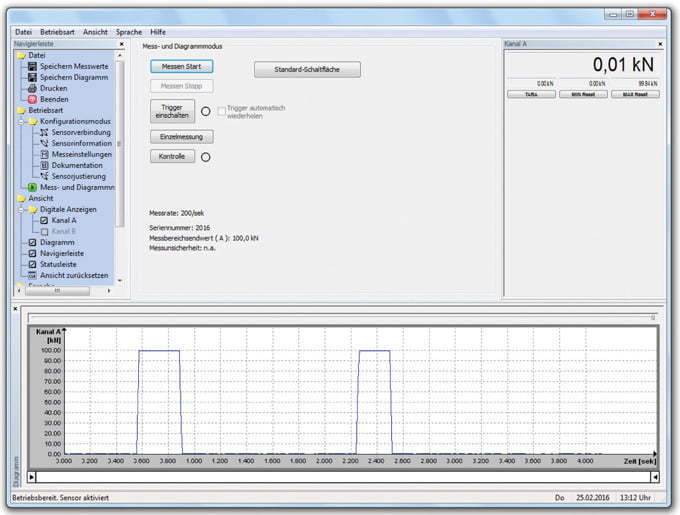

The devices from the “KENOVA measure line” product range use an LED light source for measuring. A range of diffusers and lenses collimates the LED rays, i.e. it produces a parallel alignment of the light rays. This causes the measured workpiece to cast a shadow of precisely its original size. Then a special telecentric lens captures the shadow. This workpiece profile mapped with high precision is recorded digitally and transferred to the integrated software.

The software displays a table with the measured values and the limit values as numbers on the monitor and additionally in a diagram as points on a coloured bar. If the measured value is fully within the tolerance, the bar is green. If the measured value approaches a limit value, the bar shows up yellow as a warning. When a limit value is exceeded, the bar turns red.

The import of measured values into the test report function generates the user defined report. This is then available for printing or display on the device later on. As a rule, the software creates this quality assurance report for each workpiece individually but it can also be carried out for an entire production lot of workpieces.

Simple structure and intuitive operation

The operator can independently create and store measuring programs after a short introduction phase. Provided that the screenshot of the workpiece was saved, the user can create the entire measuring program in offline mode. The drag-and-drop process facilitates this process. The pre-installed measuring macros for complicated geometries are another helpful tool, for example for measuring threads.

In live mode, the user simply places the workpiece on the precision-ground support. The characteristics are then captured automatically. The devices are equipped with a special function allowing detection of the workpiece characteristics regardless of where it is positioned. This limits human error, such as from incorrect positioning of the workpieces.

The „KENOVA measure line“ product range at a glance

The KENOVA measure line VC is used especially for larger workpieces with a maximum size of 81 x 66 millimetres. The smaller version KENOVA measure line VHE is available in two different sizes. Depending on workpiece size, the visual field is 21 x 17 millimetres or 42 x 34 millimetres. The third version, KENOVA measure line Dual, offers two devices in one compact design. This provides the option of selecting the visual field sizes (21 x 17 millimetres or 42 x 34 millimetres). One clear advantage is that workpieces of different sizes can be measured in one device.

Kelch GmbH, based in Weinstadt near Stuttgart, offers peripherals and services for manufacturers and users of machine tools for cutting processes. With over 100 employees, the company generates annual revenue of approx. €13 million. As a fully owned subsidiary of Harbin Measuring & Cutting Tool Group Co., Ltd. (HMCT), Harbin/China, Kelch is part of the China General Technology (Group) Holding Co., Ltd. (Genertec), Beijing. Genertec is represented in 100 countries worldwide, with 45,000 employees in 51 companies. Kelch GmbH acts as the technology centre for the international business group in Europe. Kelch develops, manufactures and markets tool holders, cleaning devices, shrinking devices, presetters as well as measuring machines and also offers tool management services.

More information at https://www.kelch.de.

Downloads:

KELCH_KENOVA_measure_line_VHE_VC_0902016.pdf

Image1_KENOVA_measure_line_VHE_Software_300dpi.jpg

Image1_KENOVA_measure_line_VHE_Software_72dpi.jpg

Image2_KENOVA_measure_line_VHE_300dpi.jpg

Image2_KENOVA_measure_line_VHE_72dpi.jpg

Image3_KENOVA_measure_line_VC_300dpi.jpg

Image3_KENOVA_measure_line_VC_72dpi.jpg

Image4_KENOVA_measure_line_VHE_Dual_300dpi.jpg

Image4_KENOVA_measure_line_VHE_Dual_72dpi.jpg