KELCH Smart Factory Services

3. February 2023KELCH introduces the new generation RoWi III Modular taper cleaner for tool holders

6. May 2024

KELCH Smart Factory Services

3. February 2023KELCH introduces the new generation RoWi III Modular taper cleaner for tool holders

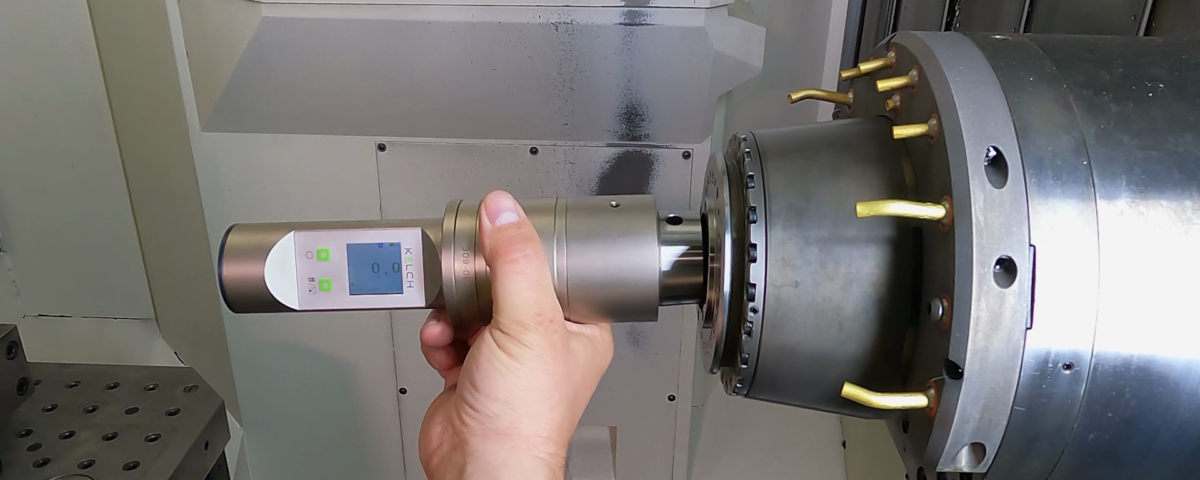

6. May 2024Safecontrol 4.0 – measuring spindle pull forces in networked production

Weinstadt, 26th June 2023 – With digital measurement of pull forces, Safecontrol 4.0 is a digital system that has a measuring range of 2 to 100 kN and can be intelligently integrated into a network with a mobile device and an app. The system records the pull forces of machine spindles, extensions, reducers and zero point clamping systems. In the app, users can also create their own set of machines and identify these with a QR code.

“Safecontrol 4.0 is ready for the smart factory and offers a valuable contribution to quality assurance, process reliability and health & safety,” says Viktor Grauer, Deputy General Manager and Head of Information Management at KELCH. The flexible measuring system allows machine manufacturers to carry out measurements quickly and reliably immediately after the clamping in the spindle. A position orientation sensor ensures convenient readout in any clamping situation.

One of a kind

When companies notice that the pull force of the machine spindle is decreasing, they can contact the manufacturer and prevent any impending damage in time. Insufficient pull forces can, for example, cause vibrations in the machine and a poorer surface quality of the workpieces. If the pull forces are very low, tools can be ejected from the machine during machining and pose a risk to workers, the machine and the materials. This would result in substantial costs for repairs and a new machine spindle, a production stop and delivery delays.

Safe processes with the app

The intuitive Safecontrol 4.0 app makes it easy and cost-efficient to set up a set of machines. All that is needed is a QR code for each spindle. This code is scanned by the camera of the mobile device and assigned to a machine spindle. Once the spindle has been assigned, the user only has to scan the QR code before starting the measurement. The associated machine is selected automatically and the system is ready for the measurement.

Downloads:

PressRelease-Safecontrol_4.0.pdf

Bildmaterial_KELCH_Safecontrol_4.0_Messung_an_DMG_Maschine.png

Bildmaterial:_KELCH_Safecontrol_4.0_Koffer.png

Bildmaterial: Messungan_DMG-Maschine-und-App.png

Bildmaterial: KELCH-Safecontrol-4.0_KurtBening_Vorbereitung_der_Messung.png

Bildmaterial: KELCH Mitarbeiter, Kurt Bening speichert die Messung mit Hilfe der App