03.09.2018 / KENOVA set line V3 with TeamViewer IoT – Press release

3. September 2018

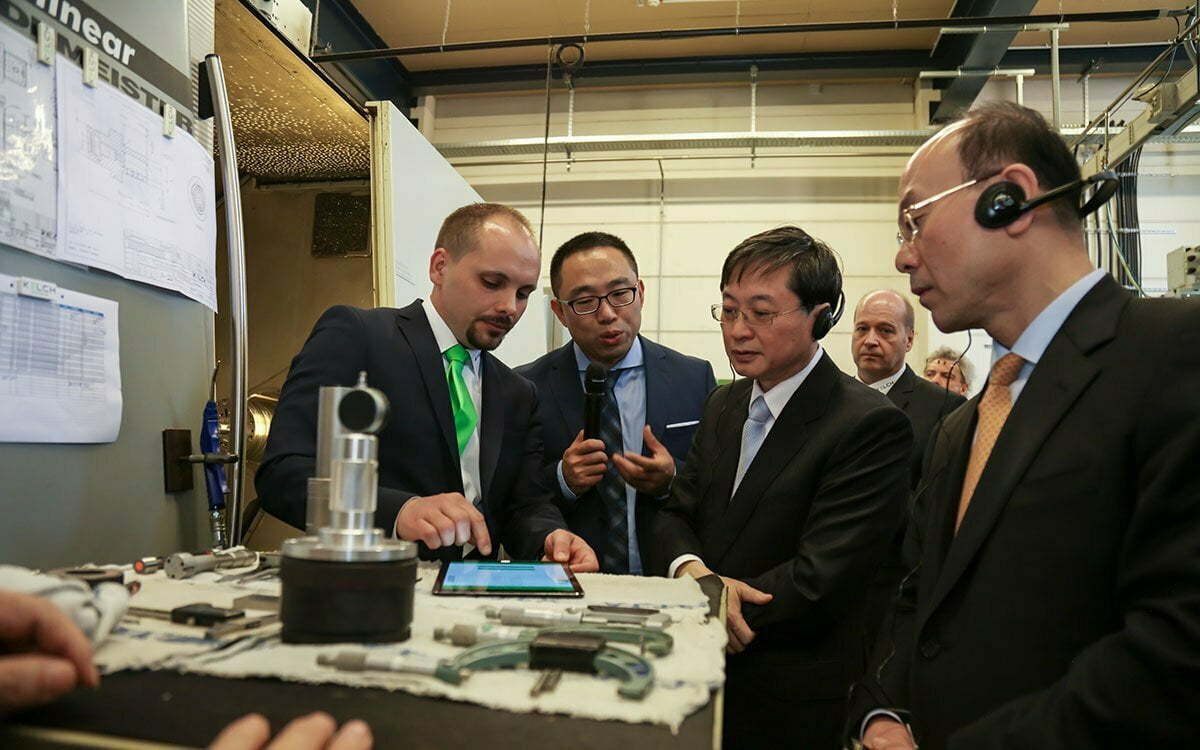

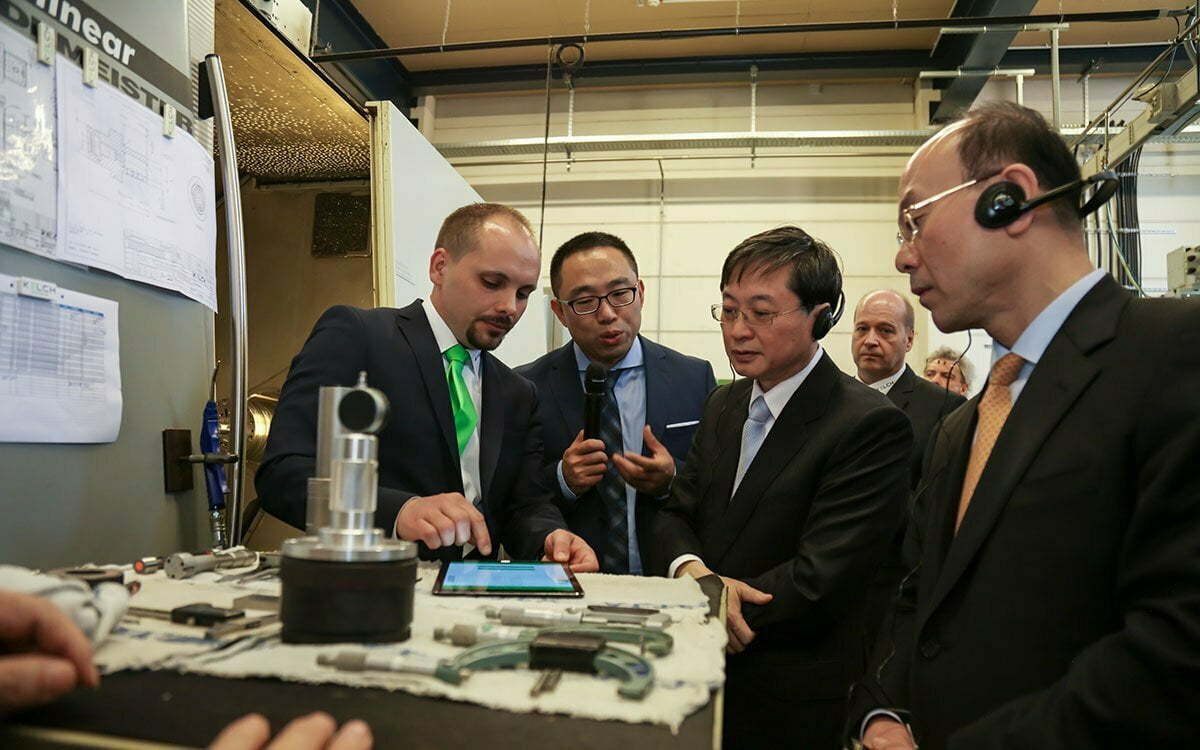

01.04.2019 / KELCH receives delegation from China – Press release

1. April 2019

03.09.2018 / KENOVA set line V3 with TeamViewer IoT – Press release

3. September 2018

01.04.2019 / KELCH receives delegation from China – Press release

1. April 2019KELCH QR – Smart Factory set-up for SMEs

Transmission of process-reliable data

Minimum time and cost outlay

KELCH at the Moulding Expo from 21 to 24.5.2019 in Stuttgart: Hall 9 / Stand C54

Weinstadt, 20 March 2019 – KELCH, the system supplier, is launching KELCH QR: a cost-effective solution enabling companies to comply with Industry 4.0 level Smart Factory standards without major expenditure. The solution is of particular interest to companies that do not wish to introduce a complete tool management system nor install cost-intensive RFID processes. Under the auspices of Industry 4.0, these companies are primarily interested in making processes more reliable and more efficient. KELCH QR improves process reliability and tool identification, but keeps costs down.

“KELCH QR is a solution for end-to-end, process-reliable tool identification, which simultaneously transmits tool data to the machine tool. Our solution can be easily and immediately integrated into the existing system landscape within a few hours. Companies can retain their existing tool numbering structures, as well as their existing machine controls,” explains Viktor Grauer (B. Eng), member of the Executive Board and Head of Innovation Management at KELCH.

QR code: efficiency in a proven environment

KELCH QR serves as a tool identification instrument and provides process-reliable data transmission – and does so on several process levels. Overall, KELCH QR delivers the following results:

• Tool identification at any time without the need for additional auxiliary equipment

• Generation of the QR code using available printers

• Process-reliable data transmission without input errors using commercially available scanners

• Greater convenience and time savings: scanning instead of typing

• Independent of the machine and control

• Minimal cost

• No costly adaptation or retrofitting required

Success in three simple steps

Step 1: A simple QR code affixed to the tool holder only contains the unique identification number of the complete tool. It is read by a hand-held scanner and the setting process can start fully automatically.

Step 2: The measured values of the tool and all machine control-related information are printed on a label encrypted as a QR code. The tool data is also written in plain text on the label. It can therefore by identified at any time, even without the need of a scanner.

Step 3: The label is conveniently read by a hand-held scanner on the machine control. A portable module enables all data to be automatically inputted into the control. Input errors are completely eliminated. The system is fully independent of the control as the input can be simulated in every controller and executed by the add-on module. The only prerequisite is an open USB connection on the control.

KELCH QR is flexible and can therefore be used on multiple machines. The system is suitable for use with all tool presetters using Easy software from version 7 onwards and kOne software.

Kelch GmbH, based in Weinstadt near Stuttgart, offers peripherals and services for manufacturers and users of machine tools for cutting processes. With over 100 employees, the company generates annual revenue of approx. €13 million. As a fully owned subsidiary of Harbin Measuring & Cutting Tool Group Co., Ltd. (HMCT), Harbin/China, Kelch is part of the China General Technology (Group) Holding Co., Ltd. (Genertec), Beijing. Genertec is represented in 100 countries worldwide, with 45,000 employees in 51 companies. Kelch GmbH acts as the technology centre for the international business group in Europe. KELCH develops, manufactures and markets tool holders, cleaning devices, shrinking devices, presetters as well as measuring machines and also offers tool management services.

More information at https://www.kelch.de.

Downloads:

KELCH_QR-Code_technology_20032019

Image1_print

Image1_web

Image2_print

Image2_ web